Project Title Market 4.0 – Approach to fully integrate the flow of information from suppliers into supply chains

Sector Metal, High-Tech

Funding/budget 100 KEUR

Short project Summary

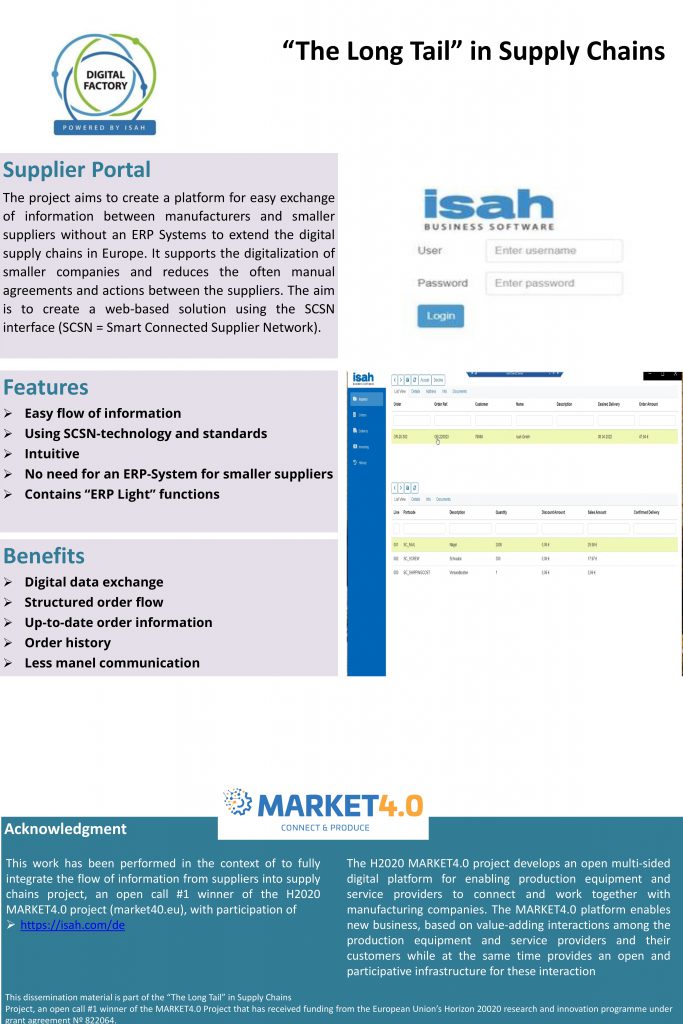

As we all know the manufacturing industry in Europe deals with several challenges. We must be very flexible to meet customer demands. The problem for companies at this point in the supply chain is that the exchange of information is interrupted by smaller companies which are not connected to an ERP System. Even for an ERP software to be used efficiently, it is dependent on input such as delivery dates and times in order to be able to carry out production planning correctly. The present project is intended to counteract this loss of information and create the possibility of providing smaller suppliers without an ERP system with the necessary information. This solution will after the POC of this project provide a relationship based on all the relevant standards like IDSA and SCSN to make exchange secure, but also not the reinvent the wheel when it comes to data sovereignty. The portal will be developed to be independent of the ERP systems. It is not linked to national borders.

Partner 1: AKM-Tore GmbH

AKM is a manufacturer of doors for the industrial and private sector. The company produces its products itself at its location in Langenhahn and looks back on a long tradition since 1983. The company manufactures its products according to customer-specific orders. No door is equal to another in its dimensions. Customers include major property developers as well as architects or dealers, who in turn represent the end customer. The company relies on a functioning supply chain for production. The administrative volume has steadily increased, so that the digitalization of the process chains has now been declared a priority corporate objective. The connection of suppliers in particular plays a central role here.

Country: Germany

Partner 2: Schubert Fertigungstechnik GmbH

Schubert has been manufacturing and supplying precision components to customer specifications for plant engineering and construction for more than 40 years. The company is part of a larger group of companies. As Schubert is more of a supply company from the point of view of the general supply chain, internal processsteps from order entry to the finished product are strongly structured and focused on efficiency. In order to meet its own standards, Schubert is constantly in touch with new production methods and technologies. As a reliable supplier, Schubert is also dependent on a functioning supplychain. A transparent exchange of information is at the heart of this.

Country: Germany

Partner 3: Pittler T&S GmbH

PITTLER – a name that stands for more than 125 years of innovation and progress in the field of turning, gear cutting and milling. The Pittler Maschinenfabrik AG is a group of companies to which another 7 companies belong. The company is active in the field of mechanical and plant engineering and operates worldwide. Pittler also represents one of the biggest industries in Germany – Maschine building. Due to its size and complex products, Pittler maintains a large, international network of suppliers. Customers include the automotive industry and manufacturing companies in metal construction. Pittler has recognized the opportunity to achieve a competitive advantage through digitalization, by offeringmachines faster and more cost-efficiently. Pittler also sees a possible reduction of the effort in the areaof supplier network.

Country: Germany

Partner 4: Karosseriewerk Heinrich Meyer GmbH

In 1882 Heinrich Meyer founded a company in Göttingen for the manufacture of company and carriage carriages. Today, Meyer develops and produces tailor-made customer solutions especially for the food market (Customers like Aldi, Lidl, Rewe, usw). Meyer’s core business is truck bodies, which are manufactured to customer specifications. Meyer has recognized the necessity of digitalization. The company not only wants to be a pioneer in its industry, but also wants to use digital solutions to reduce the need for specialists within departments in order to meet the increasingly difficult job market. The company also hopes to reduce errors in manual work, which can be handled by interfaces between systems

Country: Germany

Partner 5: Isah GmbH

In 1882 Heinrich Meyer founded a company in Göttingen for the manufacture of company and carriage carriages. Today, Meyer develops and produces tailor-made customer solutions especially for the food market (Customers like Aldi, Lidl, Rewe, usw). Meyer’s core business is truck bodies, which are manufactured to customer specifications. Meyer has recognized the necessity of digitalization. The company not only wants to be a pioneer in its industry, but also wants to use digital solutions to reduce the need for specialists within departments in order to meet the increasingly difficult job market. The company also hopes to reduce errors in manual work, which can be handled by interfaces between systems

Country: Germany