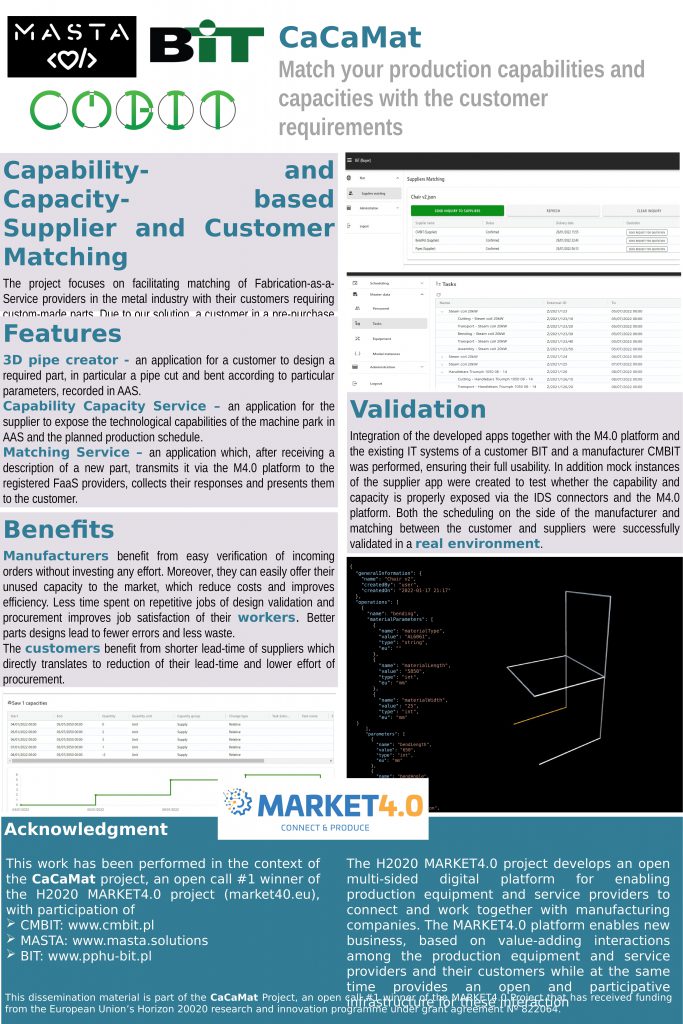

Project Title Capability and Capacity-based Supplier and Customer Matching

Sector Metal

Funding/budget 100 KEUR

Short project Summary

CaCaMat focuses on bringing new users to the Market4.0 platform and offering them unique functionalities using secure, IDS-based data exchange. We facilitate matching of Fabrication-as-a-Service providers in the metal industry with their customers requiring custom-made parts. Matching makes sure that the potential supplier has both the technological capability and capacity to deliver in minimal time. To this goal we develop a semantic model describing the fabrication operations, capabilities of the machines and scheduling operations as well as three applications – intuitive creator of custom bent elements; suppliers side application for exposing the capabilities of the machine park, validating the design, and scheduling the production; and intermediary application matching suppliers with the customer. All the applications integrate with and communicate via the Market4.0 platform.

Partner 1: CMBIT

CMBIT is a company with a large experience in metal industry related processes. The company was founded in 2007 and initially was focused on delivering control and monitoring solutions for automated production cells to widen its interest to the manufacturing of custom-made metal elements as well. CMBIT was involved in several initiatives in various domains across the world e.g., dairy industry (ArNoCo, Germany), concrete production (AIRCRETTE, Mexico) food processing (UNILEVER, France; Greece; Poland). In 2018 CMBIT was awarded one of the HORSE project application experiments grants.

Partners 2. MASTA

MASTA is built by team of professionals with proven experience in industry related information technologies. The company was founded in 2011 and from the very beginning focused on delivering Manufacturing Execution Solutions to various industry areas such as train assembly (China South Railway, Qingdao, China), plastic molding (Bianor, Bialystok, Poland) or power transmission belts (Gates, Legnica, Poland). In the recent years the company has been shifting its focus towards custom-made, IoT-based Industry 4.0 solutions and has started developing near-real time discrete production scheduling systems. Another filed of MASTA activities are AI based Predictive Maintenance solutions. The company has proven experience in delivery of business-grade software systems and a team of highly professional developers.