Project Title Integrated Software suite for component matchmaking and MAintenance planning for RoboTic GRIPpers

Sector High-tech

Funding/budget 250 KEUR

Short project Summary

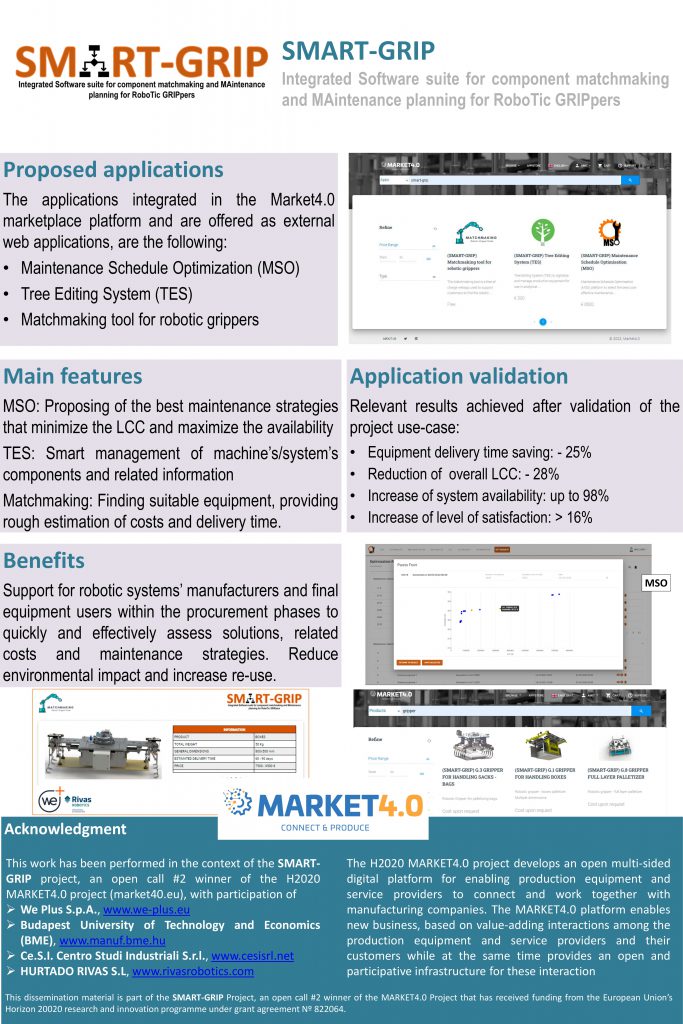

SMART-GRIP proposes an optimal maintenance allocation SW suite, applying historical data-based decision making, and a matchmaking dedicated tool for robotic gripper products. The SW suite will include the Maintenance Schedule Optimisation (MSO) tool, for best maintenance strategy and policy selection, calculating optimal maintenance schedule, minimising LCC (Life Cycle Cost), and maximising operational availability. LCC assessment, based on implemented maintenance plans, providing costs estimation associated to Reliability & Maintainability (R&M) of equipment, and R&M parameters calculation, using historical Life Data, will be considered, as well as maintenance reports generated by a separated tool called the Maintenance Support Platform (MSP). The aim is to go from TRL 6 to 8 in a 1-year project, targeting manufacturing and robotic grippers’ sectors, implementing the SW suite, with dedicated APIs, and adapted UIs to the specific addressed sectors.

Partner 1: We Plus S.p.A. (WEP)

We Plus S.p.A. (WEP) is an Italian IT SME accounting for about 90 employees. WEP offers complete IT development services following its expertise and core competencies like: Programming languages: Java, C#, Python, PHP, C, C++; Distributed Computing / Big Data: Hadoop, Apache Spark, Cloudera; Databases: SQL Server, Oracle, MySQL, SQLite, MongoDB; Application Servers: WebLogic, IIS, WebSphere, Tomcat; Web Technologies: J2EE/JEE, JSP/Servlets, EJB, JMS, JTA, XML, XSLT, XPath, XQuery, Struts, PL/SQL, T-SQL ASP.NET, .Net Web Services, WPF, WCF, REST Services, Spring, Javascript, JSON, jQuery, AJAX, HTML, CSS; Tools: NetBeans, Visual Studio, Eclipse, TOAD, Apache ANT, CVS, VSS, SVN, SQL Server Integration Services (SSIS), Microsoft Visio, ERWin, RationalRose, Crystal Reports, Business Objects; Other skills: BI (Business Intelligence), ETL (Extract Transform Load), Data Warehouse, OOP (Object Oriented Programming), OOA (Object Oriented Analysis), Agile, UML (Unified Modelling Language); Mobile Platforms: Android, iOS, Windows Phone, BlackBerry; Operating Systems: Windows, Linux, Unix, MAC; Cloud: MS Azure, Amazon AWS. WEP is working to manage and develop many projects in various sectors: utilities / manufacturing, energy, telecommunications, system integrators, banking, insurance, financial, and more.

Partner 2: Budapest University of Technology and Economics (BME)

BME founded in 1782, with eight faculties is the largest technical higher education institution of Hungary. The proposed work will be carried out at the Department of Manufacturing Science and Engineering (DMSE). The department is active in the areas of theory of metal cutting; planning, simulation, diagnosis and monitoring of production processes; design, maintenance and reliability of machine tools; planning and design of manufacturing systems; assembly automation; robot applications and gripper design; service robots including medical robotics, testing and control of robots; CAD/CAM; quality assurance; scheduling, control and simulation of manufacturing systems; artificial intelligence in manufacturing engineering. The department has been taken part in 7 FP4, 4 FP5, 7 FP6, 3 FP7 and 2 H2020 projects. R&D results related to the proposed work: BME DMSE have developed methods and tools for discrete event simulation model configurators; process planning, scheduling and production control methods and tools using various AI techniques; reliability and maintenance as well as end of life related analysis and prediction methods and software tools.

Partner 3: Ce.S.I. Centro Studi Industriali S.r.l. (CESI)

CESI is a highly specialized engineering company (SME) that operates mainly in mechanical engineering field. CESI is involved in mechanical design, CAE/FEM structural analysis, R&M simulation/analysis, research and innovation activities for production equipment market. The company specialises in development of innovative products from the point of view of high performances as well as reliability, maintainability, modularity, flexibility, innovative materials application and quality. CESI has assumed a key role at international level in defining and designing different kind of systems like high performances multi-axis machining centres (for aerospace/automotive component manufacturing); AWJ machines, micro-machining modules and smart structures. CESI competences has been enlarged to offer also manufacturing services in the field of precision machining. CESI manufacturing capabilities include the processes and equipment (including CNC turning, 5-axis milling, integrated turning/milling, surface grinding, 3D measuring) required for fabrication of a wide range of products in the fields of automotive, motorcycle, aerospace, machine tools, printing machines, industrial plants, medical and microelectronics industry as well as mechanical components. CESI is participating at several European and national R&D projects. The high qualified engineering staff together with the permanent world-wide collaboration with the most important universities and excellence research centres allows CESI to achieve very important industrial results and increase its own and customers’ competitiveness.

Partner 4: HURTADO RIVAS S.L // RIVAS ROBOTICS (RIVAS)

Spanish company with more than 60 years. Specialized in the design and manufacture of robotic and industrial automation installations for multiple sectors. With the incorporation of the 4th generation, it was decided to diversify the family business by creating a special line of Robotics and industrial automation. With this new area RIVAS managed to diversify both in the sector and in the commercial area. RIVAS has specialized in providing solutions in robotics and industrial automation in multiple sectors: the following sectors are the ones of greater implantation: food, food industry suppliers, plastic and wood.

RIVAS commercial network covers both the national and international market. RIVAS has an extensive large work structure; being a manufacturer, it has its own commercial network directed by Sales Manager and an Export Manager. RIVAS has its own engineering team. It is directed by a Technical and Production Director and includes two areas – “Mechanical Engineering” and “Electrical Engineering and programming”, with a team of about 10 people. The Production area also has a Head of Workshop directed by the Technical and Production Director, with a technical team that includes the different technical profiles necessary for the manufacture and implementation of the facilities.